Stainless Steel Braided Hose for Brake & Clutch

|

A Full Range of Hose Assemblies are available to Customer Requirements in Crimped configuration.

|

The exceptional resistance of PTFE to high temperatures, permeably, chemical attack, water resistance and its low friction properties make it an ideal choice for motorsport applications.

Other benefits include high working pressures and an extremely wide range of end fitting configurations. JLS Brake Hose 4011 has a PTFE core, with an improved closely controlled braid specification that provides a greatly increased resistance to volumetric expansion, resulting in a positive and responsive brake and clutch pedal. For larger size hose on fuel and lubrication JLS PTFE hose also has many advantages. Because of its smooth bore, this series provides an uninterrupted passage for fuels and oils, thus eliminating the starvation and cavitational problems sometimes associated with convoluted hase when high flow rates are used. The stainless steel outer braid offers excellent resistance to heat, abrasion and mechanical damage and will not absorb oil and fuel into its braiding, thus eliminating weigh gain. Construction:. • Inner Core: Extruded smooth bore PTFE Resin. • Reinforcement: One layer of 304 wire braid. • Temperature Rating: -55°C to +232°C (-67°F to +45°F). • Couplings: Re-useable or permanently attached. • Applications: Brake, Clutch, Instrumentation, Fuel & Lubrication. • PC: Clear extruded outer cover to prevent damage to the stainless steel braid. • C: Carbon Lined to prevent static build-up. • Colours: BE-Blue, RD-Red, PC-Clear, HB-Black. |

|

For further details of our Fitting Range please see our Catalogue section of this website

|

Stainless Steel Hose for Fuel & Oil Lines

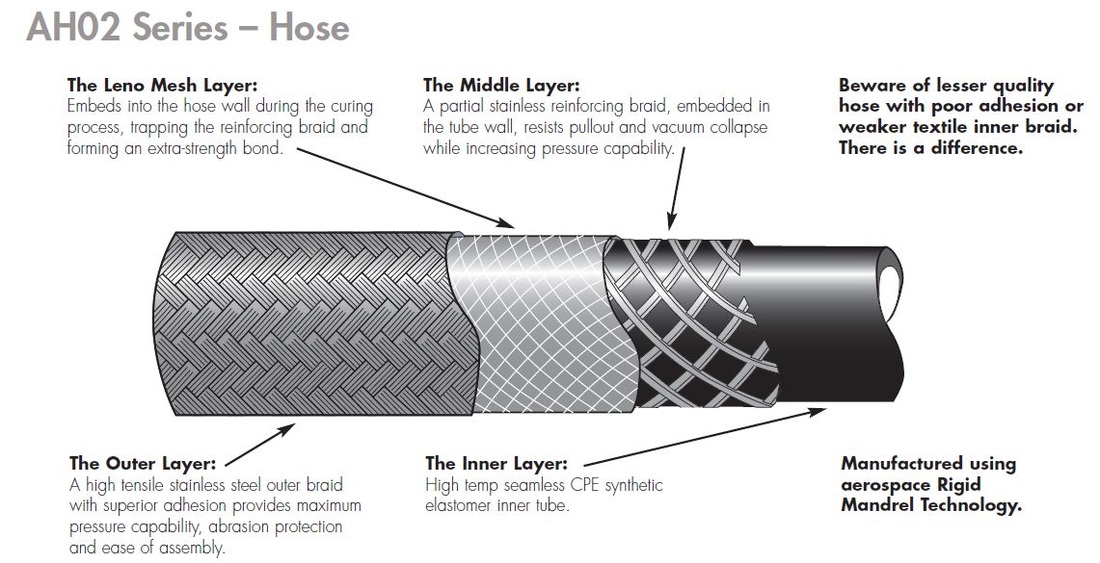

Type AH02 Rubber/Stainless Braided Racing Hose AH02 series hose is an extremely flexible full competition race hose. Externally the hose is protected from abrasion and corrosion by its 304 HC outer braiding. The compact nature of the braid construction ensures a tight bend radius, an important feature often demanded by many motorsport applications. Its high grade synthetic rubber innercore provides excellent compatibility with fuels, oils, coolants, lubricants, hydrocarbons and alcohol’s.

A large selection of end fittings are available for AH02 hose, details of which can be found on the following pages. Also available to suit all hose is our “XRP Fire Sleeve” for added protection against heat and abrasive surfaces.

• Inner Core: Seamless synthetic Rubber compound

• Re-enforcement: Stainless Steel wire braid consisting of partial inner braid & full cover outer braiding to AISI 304

• Temperature Range: -54°C to +150°C (-65°F to 300°F)

• Fittings: Re-usable

• Applications: Fuel, Oil & Coolant Systems

• Due to continual hose development specification may vary from above

A large selection of end fittings are available for AH02 hose, details of which can be found on the following pages. Also available to suit all hose is our “XRP Fire Sleeve” for added protection against heat and abrasive surfaces.

• Inner Core: Seamless synthetic Rubber compound

• Re-enforcement: Stainless Steel wire braid consisting of partial inner braid & full cover outer braiding to AISI 304

• Temperature Range: -54°C to +150°C (-65°F to 300°F)

• Fittings: Re-usable

• Applications: Fuel, Oil & Coolant Systems

• Due to continual hose development specification may vary from above

|

For details of fittings please see our Catalogue section

|